Min.Order : 1 Pieces Quick Quotation >

Conpany Profile

Product Details

If you are checking hide gelatin line kdscx price, or looking for cheap high torque hide gelatin line kdscx, welcome to contact KODI Machinery, we are one of the leading China hide gelatin line kdscx manufacturers.

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Brand Name: KODI

Model Number: No

Type: gelatin

After-sales Service Provided: Engineers available to service machinery overseas

Product Name: KODI High Quality Hide Gelatin Production Line

Gelatin capacity: 750-3000 ton/year

Gelatin Moisture: 10-12 %

Feeding concentration: 28-32 %

Bloom gelatin strength: 150 g

Coolant: 20000-75000 kcals/h

Steam consumption(0.4Mpa): 570-3220 kg/h

Material: stainless steel or carbon steel

Spare parts: Supply the whole lifetime

Installation: KODI service

Packaging & Delivery

| Packaging Details: | KODI High Quality Hide Gelatin Production Line /Hide gelatin machine /Hide gelatin line is packing with plywood box or As customers' requirement |

|---|---|

| Delivery Detail: | 45-90days |

KODI High Quality Hide Gelatin Production Line

1, Hide Gelatin Production Line / Hide gelatin machine / Hide gelatin line

2, stainless steel

3, high efficient

4, simple operation and easy maintenance

5, Halal product

Product Description

What is Hide

Hide is an animal skin treated for human use. Common commercial hides include leather from cattle and other livestock animals, buckskin, alligator skin, and snake skin. All are used for shoes, clothes, and otherfashion accessories. Leather is also used in upholstery, interior decorating, and horse tack and harnesses. Such skins are sometimes still gathered from hunting and processed at a domestic or artisanal level but most leather makingis now industrialized and large-scale. Various tannins are used for this purpose.

The term "hide" is sometimes expanded to include furs, which are harvested from various species, including cats, mustelids, and bears.

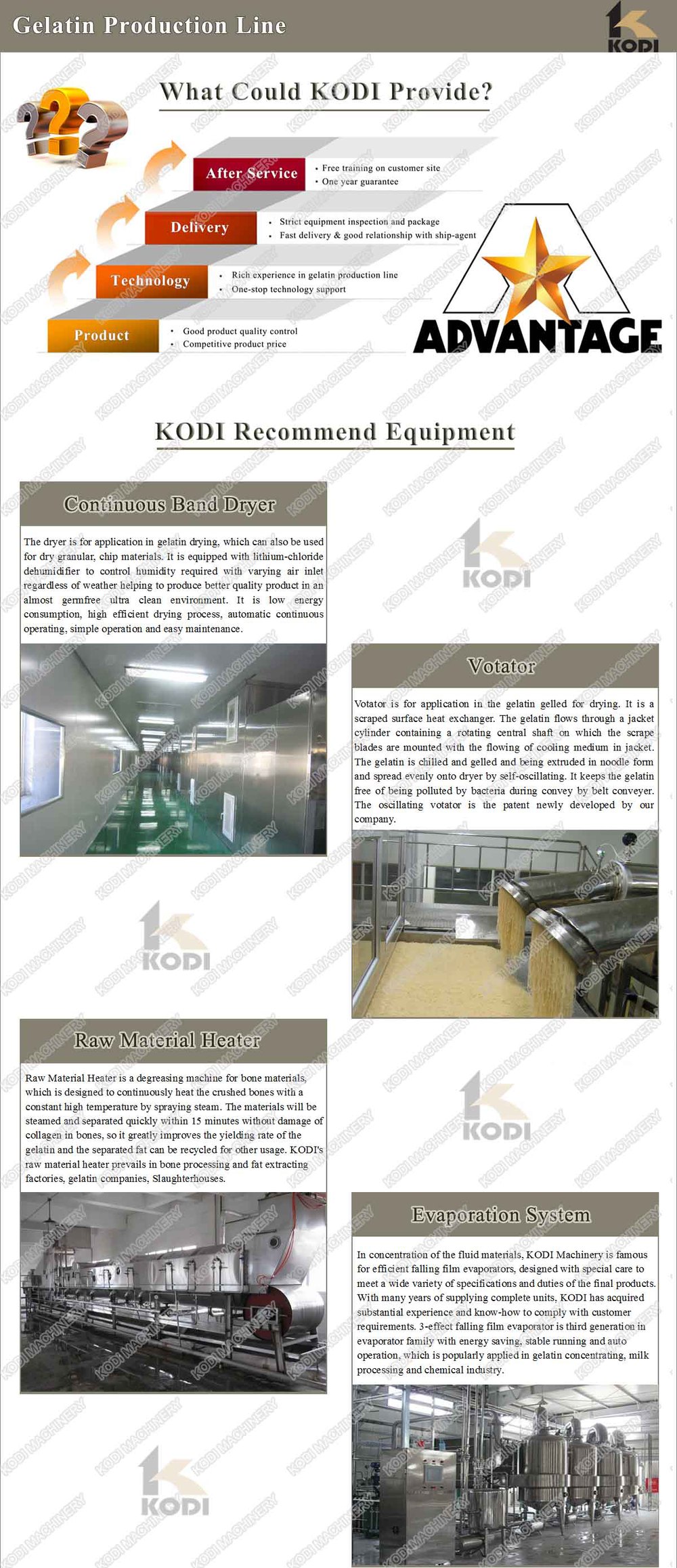

Main Equipment of Hide Gelatin Production Line

Sucessful Project of KODI Hide Gelatin Machine

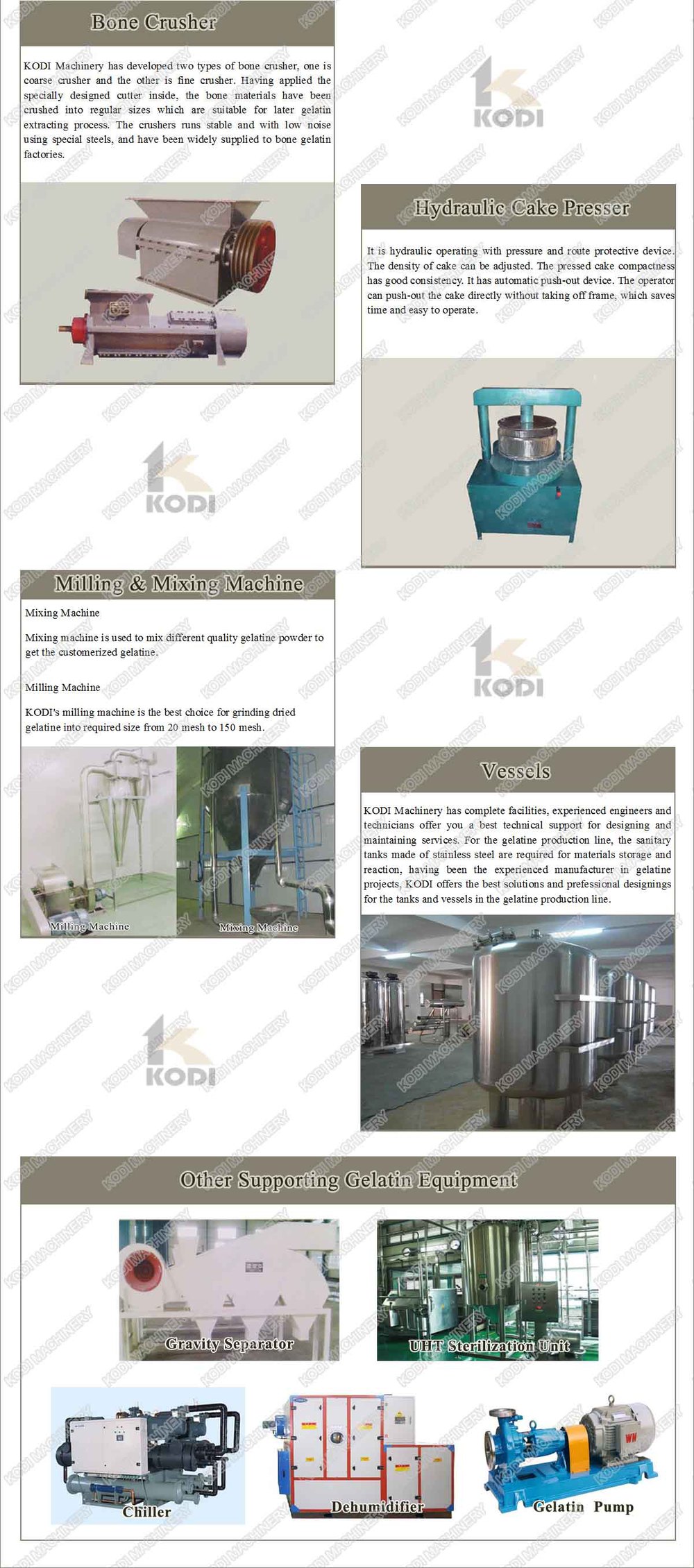

About Gelatin

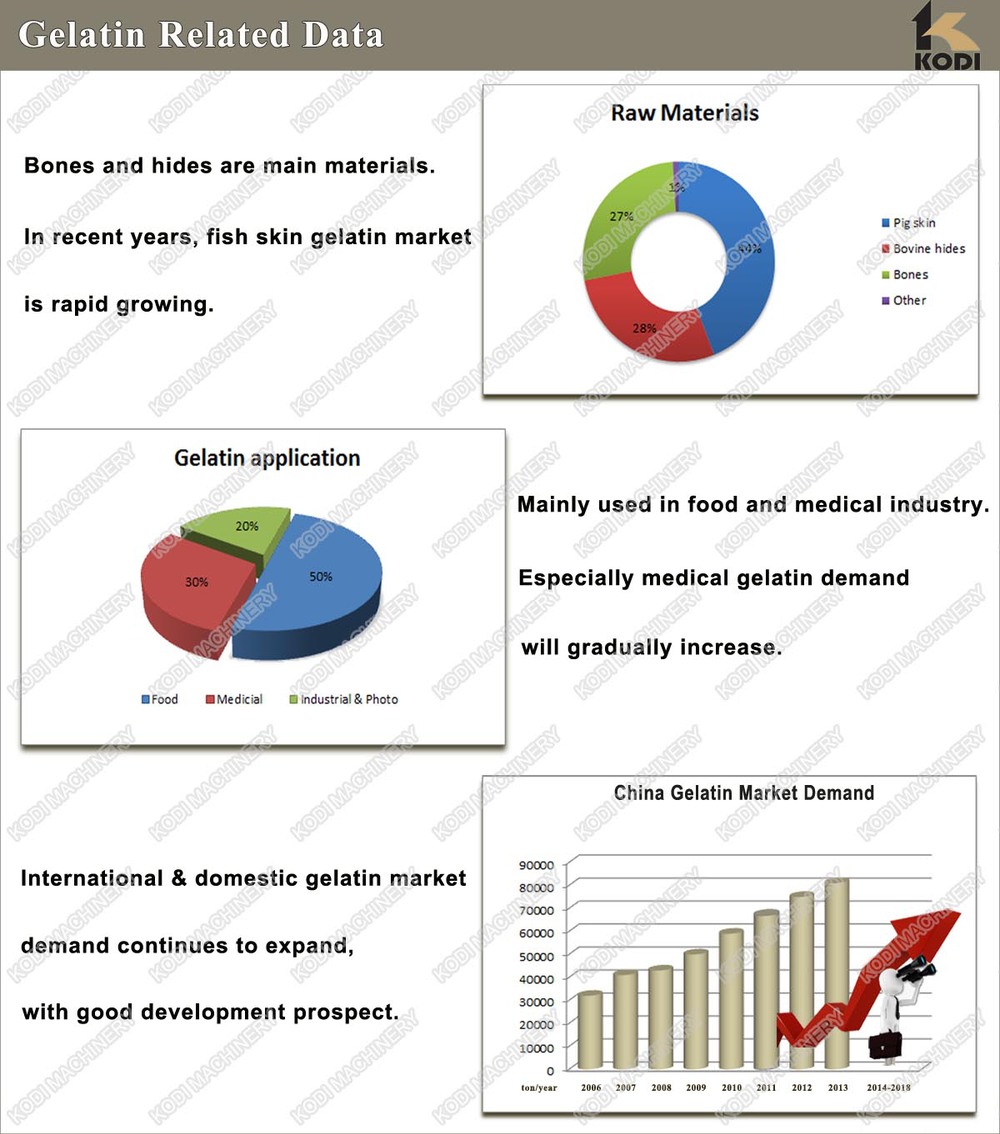

Gelatin is a protein substance derived from collagen, a natural protein present in the tendons, ligaments, and tissues of mammals. It is produced by boiling the connective tissues, bones and skins of animals, usually cows and pigs. Gelatin's ability to form strong, transparent gels and flexible films that are easily digested, soluble in hot water, and capable of forming a positive binding action have made it a valuable commodity in food processing, pharmaceuticals, photography, and paper production.

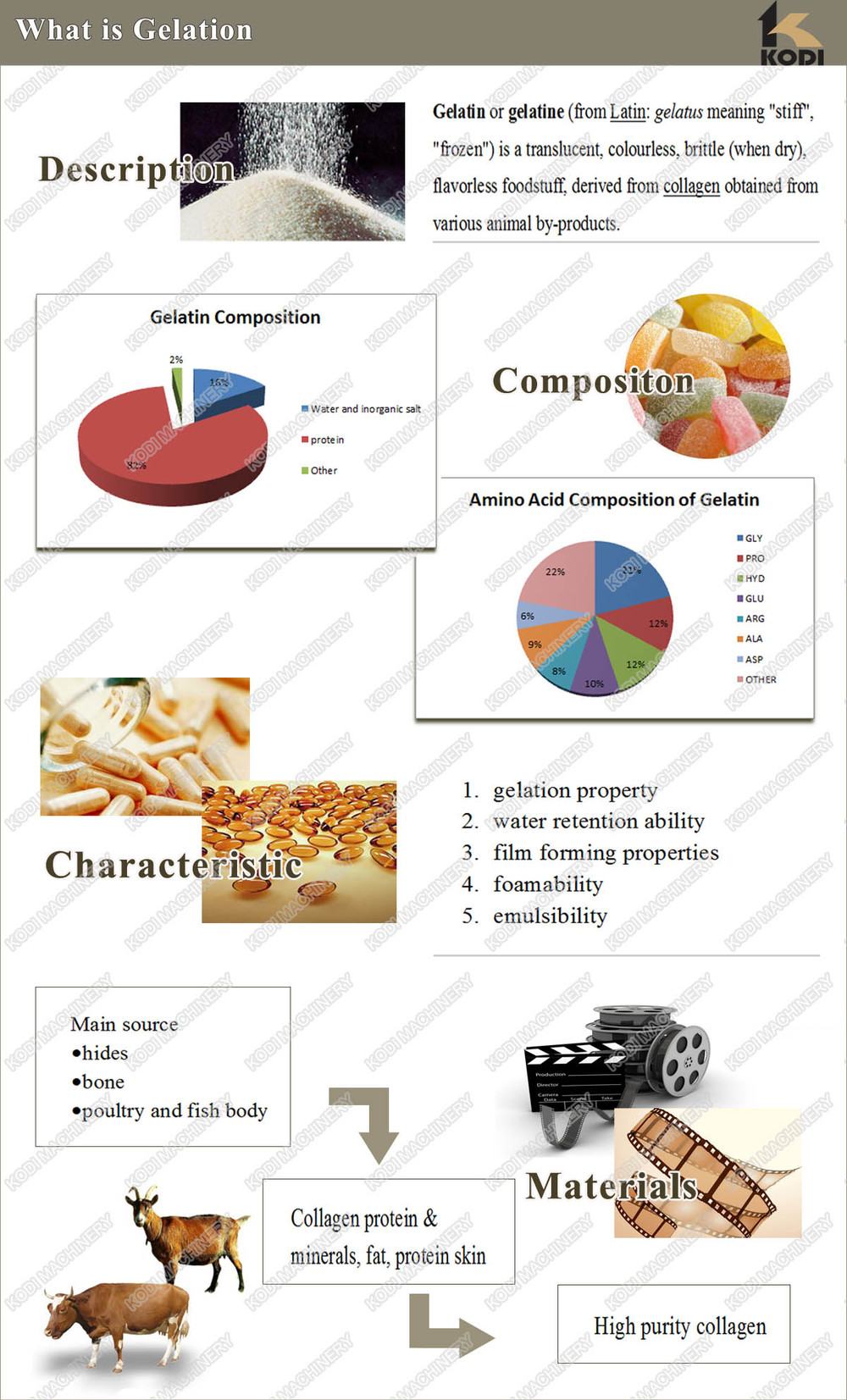

Gelatin Wide Application

Culinary uses

Probably best known as a gelling agent in cooking, different types and grades of gelatin are used in a wide range of food and non-food products: Common examples of foods that contain gelatin are gelatin desserts, trifles, aspic, marshmallows, candy corn, and confections such as Peeps, gummy bears, fruit snacks, and jelly babies. Gelatin may be used as a stabilizer, thickener, or texturizer in foods such asyogurt, cream cheese, and margarine; it is used, as well, in fat-reduced foods to simulate the mouthfeel of fat and to create volume without adding calories.

Gelatin is used for the clarification of juices, such as apple juice, and of vinegar. Isinglass, from the swim bladders of fish, is still used as a fining agent for wine and beer.[7] Beside hartshorn jelly, from deer antlers (hence the name "hartshorn"), isinglass was one of the oldest sources of gelatin.

Technical uses

Certain professional and theatrical lighting equipment use colour gels to change the beam color. These were historically made with gelatin, hence the term color gel.

Gelatin typically constitutes the shells of pharmaceutical capsules in order to make them easier to swallow. Hypromellose is a vegetarian-acceptable alternative to gelatin, but is more expensive to produce.

Animal glues such as hide glue are essentially unrefined gelatin.

It is used to hold silver halide crystals in an emulsion in virtually all photographic films and photographic papers. Despite some efforts, no suitable substitutes with the stability and low cost of gelatin have been found.

Used as a carrier, coating or separating agent for other substances; for example, it makes beta-carotene water-soluble thus imparting a yellow color to any soft drinks containing beta-carotene.

Gelatin is closely related to bone glue and is used as a binder in match heads and sandpaper.

Cosmetics may contain a non-gelling variant of gelatin under the name hydrolyzed collagen.

Gelatin was first used as an external surface sizing for paper in 1337 and continued as a dominant sizing agent of all European papers through the mid-19th century. In modern times it occasionally found in some glossy printing papers, artistic papers, playing cards, and it maintains the wrinkles in crêpe paper.

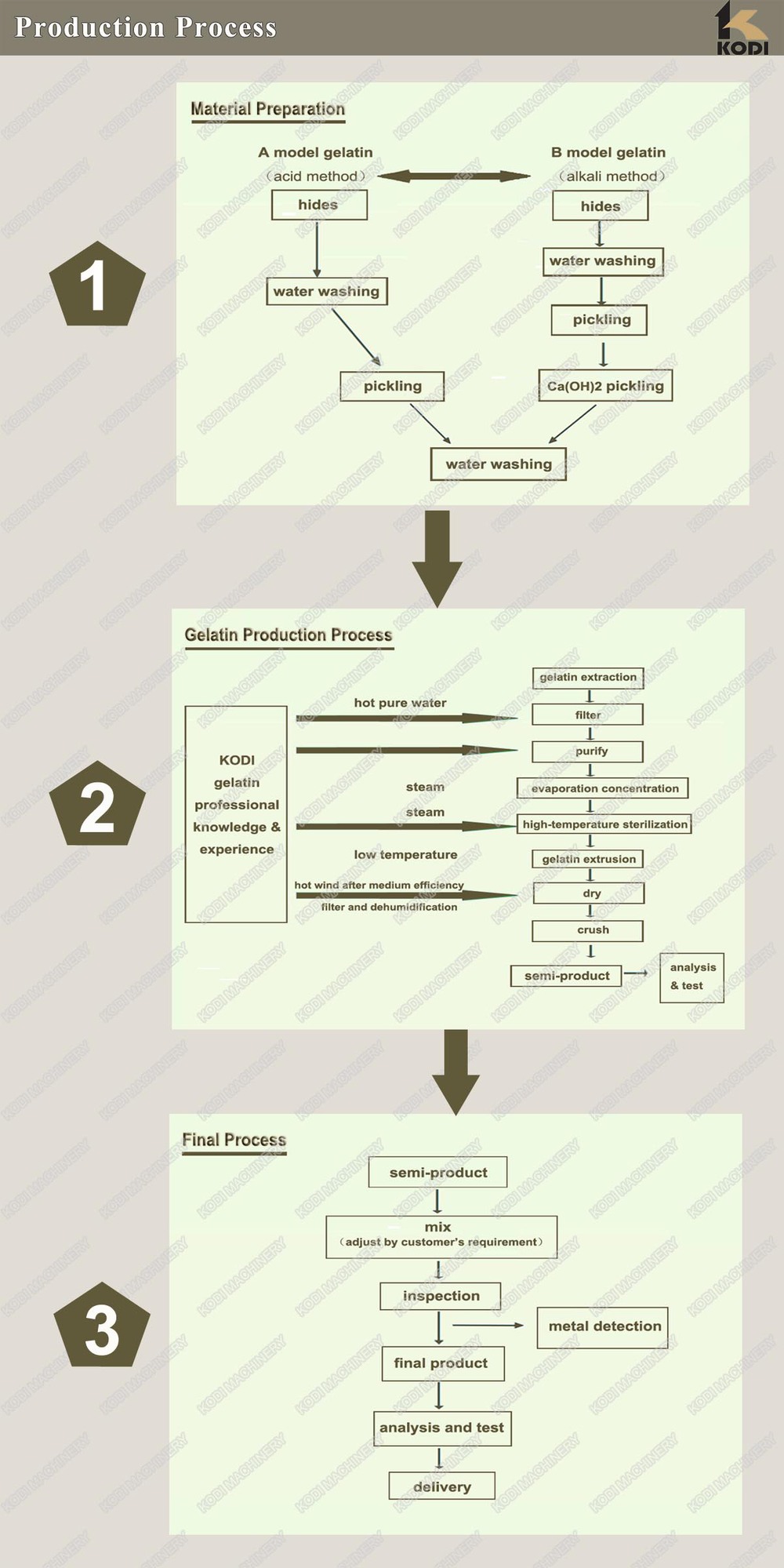

Hide Gelatin Production Methods

Hide Gelatin Production Methods

Step 1: The

material that actually becomes gelatin is collagen. This is only found

in high enough concentrations to be useful inside skin and bones. As a

result, the first step in gelatin production is cleaning the starter

materials in KODI Gelatin washing tanks. Any leftover debris, such as

fat, hair or meat, is thoroughly scrubbed from the skin and bones. This

reduces the chance of contaminants, which creates a purer product and

easier extraction.

Step 2: This next part of gelatin production is where the methods begin to diverge in KODI Gelatin acid tanks or KODI Gelatin Alkaline tanks. The base material is soaked in a solution, which begins to break down the links between the collagen and other materials using one of three basic soaking methods: acidic, alkaline and enzymatic. Acidic methods for gelatin production typically take one to two days and work the best on hides. Alkaline methods can take weeks but will work on nearly any valid material. Lastly, enzymatic processes are somewhat new but work very fast and produce high purity in the few places equipped to use them.

Step 3: The rest of the gelatin production process is done fairly quickly. After the soaking in KODI Gelatin soaking tanks, the collagen is pulled from the base material using water. Alkaline water will pull the material faster, but will also damage the gelatin, so neutral or acidic water is generally used. Heat will also damage the collagen but will generally pull out more material, so washing is done in waves. The process starts with cold water but gradually gets warmer to get as much out as possible.

Step 4: The last step processes the collagen into full-fledged gelatin. This part of gelatin production varies wildly based on the previous steps, but it typically involves cold temperatures, filtration and air drying systems. Here we normally need to use KODI gelatin membrane filter, KODI gelatin belt dryer/ Band dryer. Different pH levels and ambient temperatures during soaking have a large impact on the solidity and quantity of the final product. KODI company will supply you a Turnkey skin/hide/bone gelatin production line and Gelatin machinery.

Hide Gelatin Simple flow chart

Recommend Product