Plastic Injection Overmolding Parts

Min.Order : 1 Pieces Quick Quotation >

Conpany Profile

Product Details

Our advantage:

1.Directly Factory injection mould maker

2.Taking concepts to reality

3.Over molding, single cavity mold,insert molding, multi-inser molds, insert changeable injection mould, changeable slides mould.

4.More than 6 Years injection mold and plastic parts export experience

5. The bigest projest we do is total 32 molds for SCHNEIDER in UK.

Product Description

Product description:

| Category | mold |

| Mould Life | 100,000~1,000,000 shots |

| T1 Time | 3~18 weeks for plastic injection molding , 7-15 days for molded plastics |

| Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mould Base | LKM Standard, HASCO Standard Self-made, etc. |

| Steel Material | P20, 718H, 718HH, 2.738, 1.2343, 1.2344, H13, S136, SKD61, etc. |

| Steel Supplier | Buderus(Germany), Assab(Sweden), Finkl(USA), LKM(China), Baosteel(China), etc. |

| Product Material | PP, ABS, ABS+PC, TPE, PC, PMMA, BMW, PA, POM, PVC, PE, Aluminum, etc. |

| Design software | NX_UG, Pro/E, Catia, Moldflow, AutoCAD |

| Hot Runner | Synventive, Moldmaster, HRS, Incoe, Sino, Yudo, etc. |

| Gate | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Hydraulic | Parker, SMC, Junfan, etc. |

| Ejection Type | Stripper Plate, Lifter, Push Bar, Ejection Pin, etc. |

| Valuable Service | High polishing, Grainning, Texture, etc. |

| Parts Delivery | DHL or UPS,Air Freight or Sea Freight |

About Us:

We are a manufacturer specializing in plastic mould/mold and moulded plastic parts in Shenzhen, China.

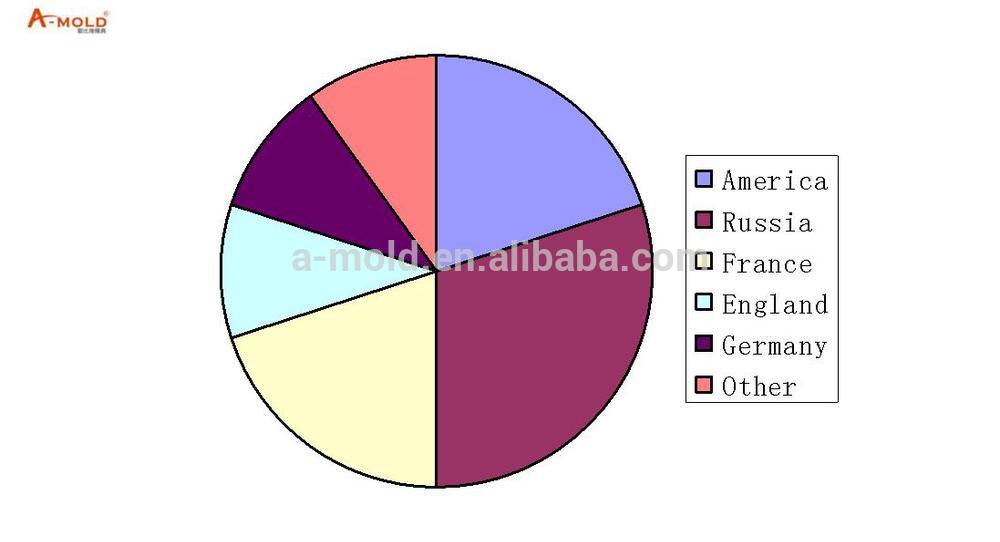

We export many moulds and plastic products to USA, UK, FRANCE, GERMANY, ITALY, AUSTRIA,RUSSIA, USA,etc. our customers are satisfied with our quality and services.

Company Profile:

•Factory Area: 5,000 square meters

•Total Employee: 70 employees

•Output Ability: 200~400 molds per year

•11 injection mold machine(120T-250T)

•1 CMM machine, we can do better on size measure.

•Design and Engineering Experiences

•Unscrew Mould

•Insert Mould

•Interchangeable Mould

•Multiple Slide Action Mould

•Stripper and Floating Cavity Plate Mould

•Hot Runner System Mould

•2 Nozzle Rotary Mould

•Gas Injection Mould

| Compay | Abery Mold & Plastics Co., Ltd |

| Main Products | Plastic mold for electronical part, automotive part, household appliance, precise appliance, etc. |

| Business Type | Mold and molded parts |

| Country Of Origin | Shenzhen,China. |

| Number of Employees | 60 people |

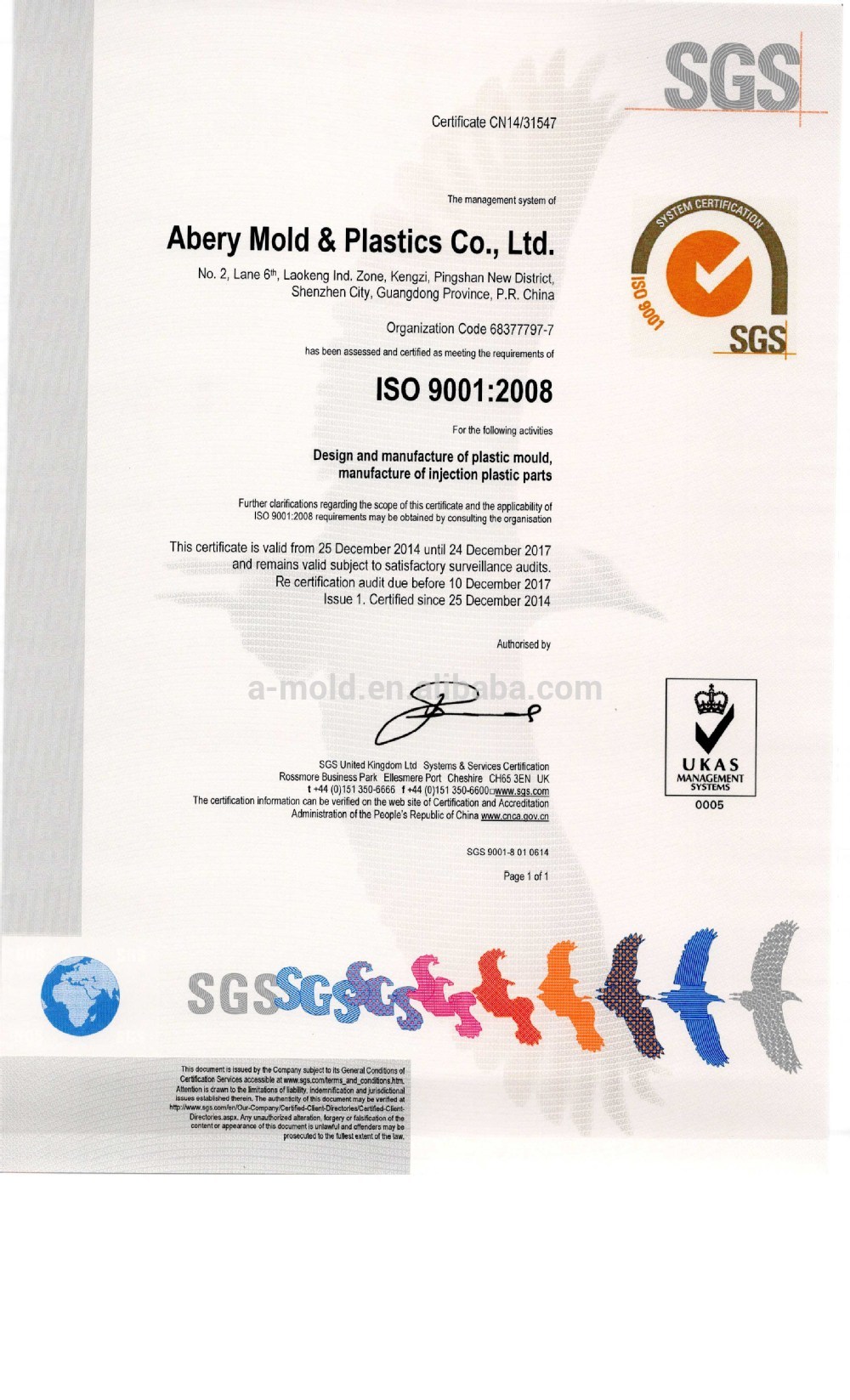

| Quality System | ISO9001:2008 |

| Export Country | Europe, North America, South America, Asia, Middle East, etc. |

| Export Percentage | 85% |

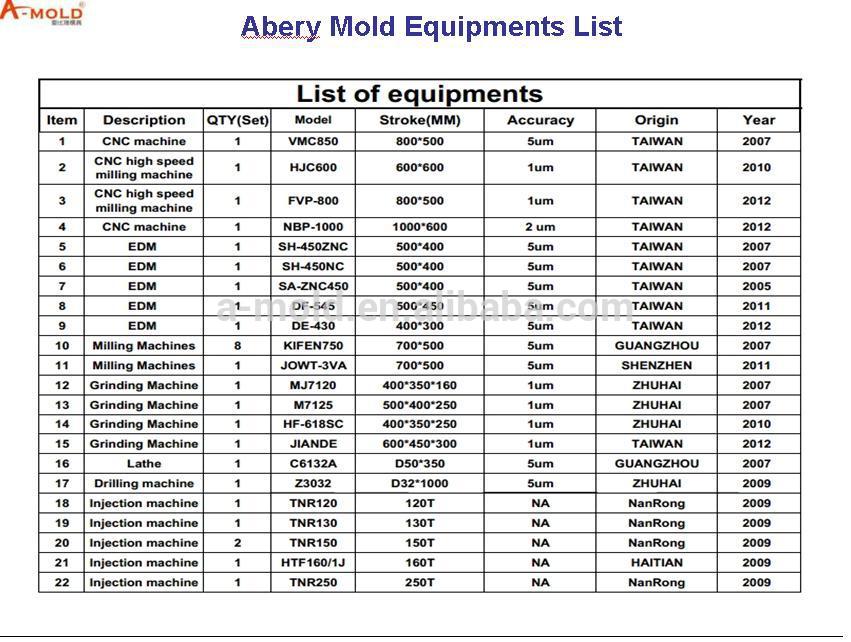

2).Our equipment:

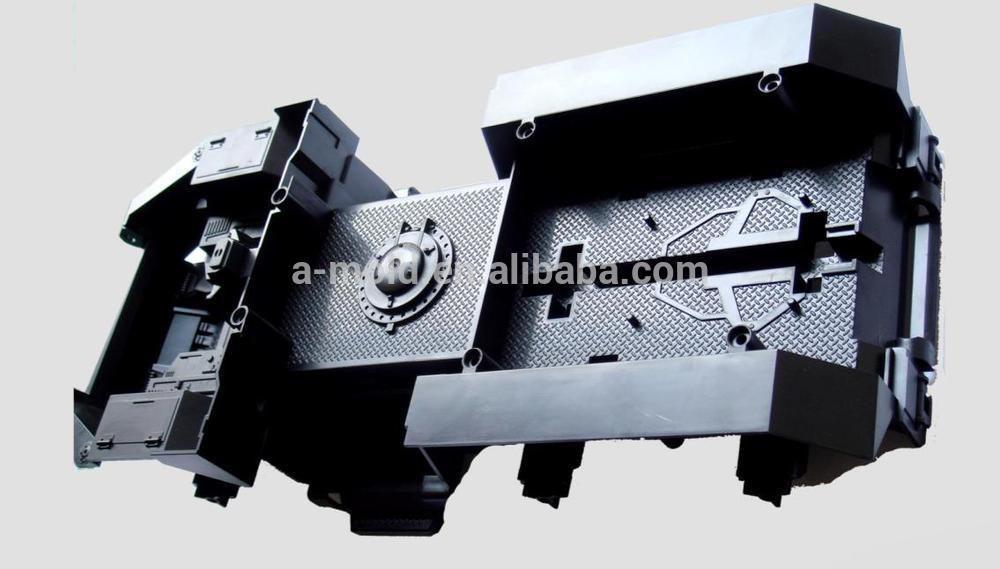

3).Our mold moulded parts samples:

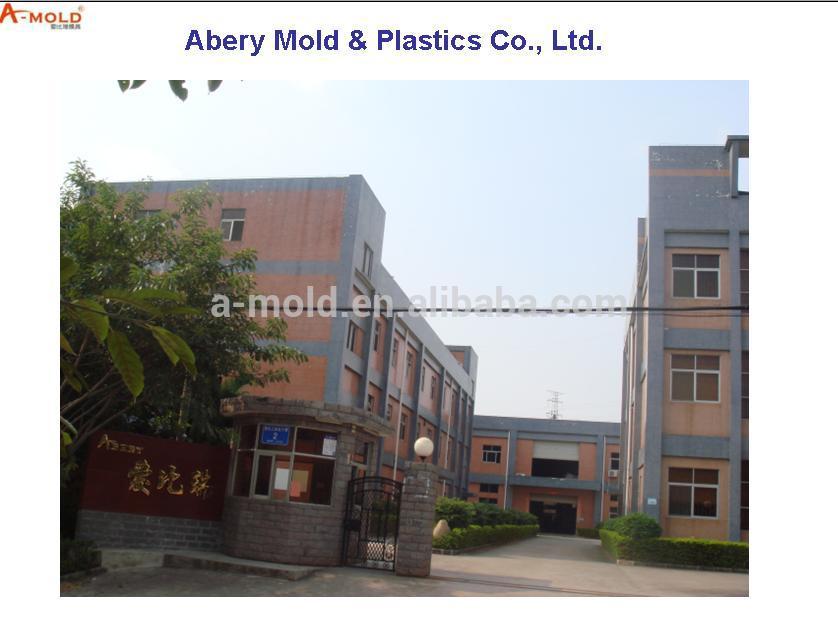

4).Our factory:

5) Our certificate

Packaging & Shipping

Wooden case for plastic mould,Carton for molded plastic parts

FAQ

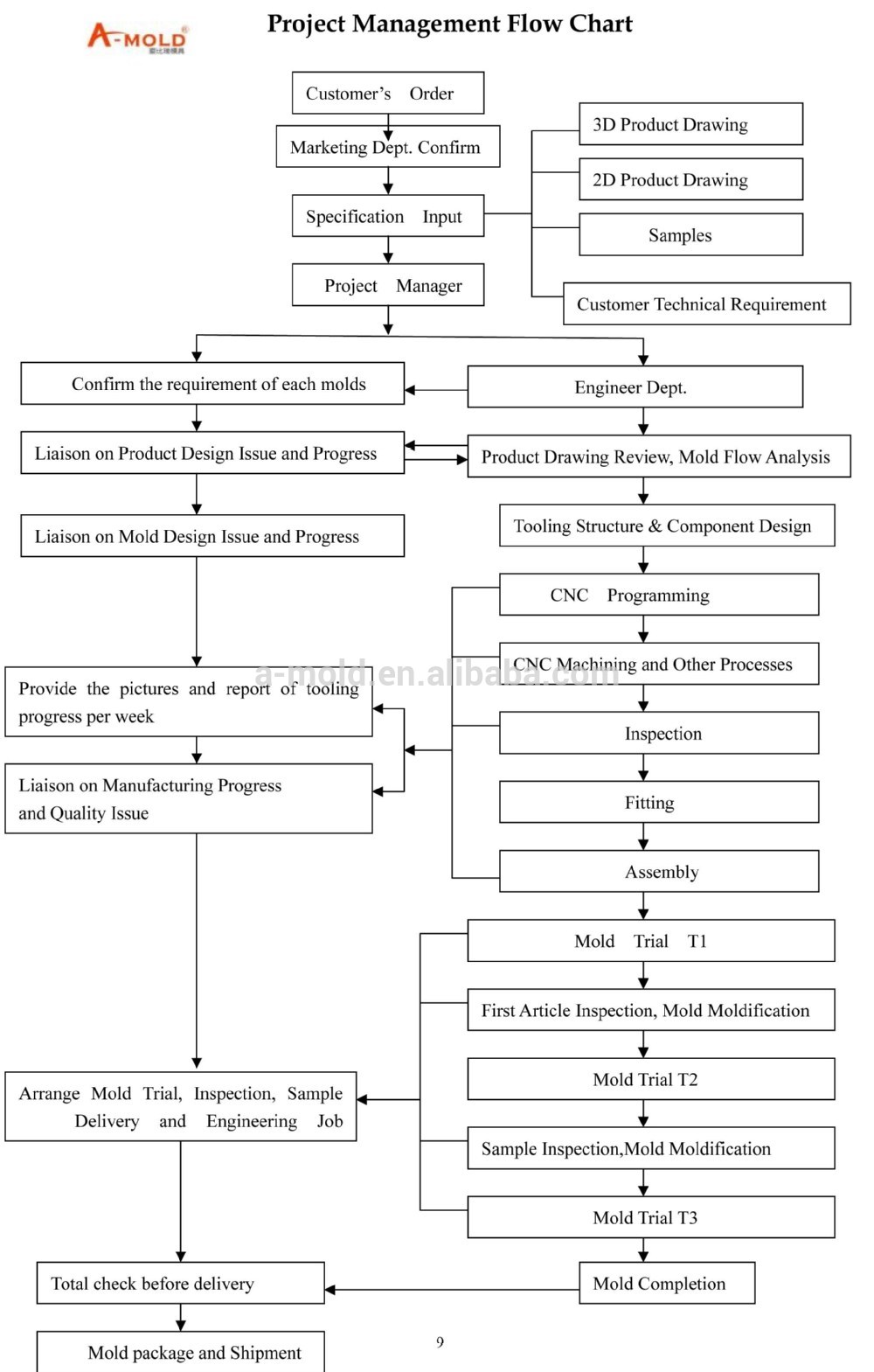

Injection mould project flow chart

our business

Injection mould making in the world

Q. What’s your inspection quality level?

Level A/ Leve B/ Level C

Q. How many days for the mold building ?

It depend on the plastic parts size. We can confirm to you at the begging of the order.

Q.How to inspection plastic injection mould quality ?

1.Mould material Q/C, include mould steel checking(Hardness, flaw checking), mould standard spare parts checking( hardness, size, flaw checking).

2.Mould making process QC, include design checking( part design, mould design, mould engineering drawing). Each part of mould’s size checking after matching according to 2D drawing, mould testing ( check mould running condition)

3.Check with customer’s requirement again before mould shipping.

Q. How to maintenance your plastic mould ?

When the mould is vacant, spray the anti-rust oil, clean the gate and cooling system , no recycled material to be use.

Q. How we check the mold ?

We will send you the mold building process image every week or you can visit our factory yourself, also we can send you the mold testing video for reference.

Q. Which countries your injection mould tooling export?

USA, UK, Germany, France, Russia, Japan, India etc.

Q. Do you have your own mold building workshop?

In house mold design and building capabilities.

Q. Do you use reclaimed material ?

We never and ever use reclaimed material.

Q. Does our design safe in your factory?

We keep secret to your idea and your design from part design to mold design.

Q. Can you give us some suggestions on how to build the molds ?

Yes, we will review your product and plastic design and offer some suggestions according your requirement.

Q. How many people work in engineering department ?

5 engineers

Q. How many mold you make per month

Around 30 molds per month.

Q. Do you have any experience work with famous companies?

Yes, we service to SCHNEIDER UK, LENNOXIN USA, MCLAREN UK

Recommend Product